Copper-Coated Steel Fibers: Hybrid Conductive Reinforcements for Advanced Composites steel fibre manufacturers

- by admin

1. Material Composition and Interfacial Design

1.1 Core-Shell Framework and Bonding Mechanism

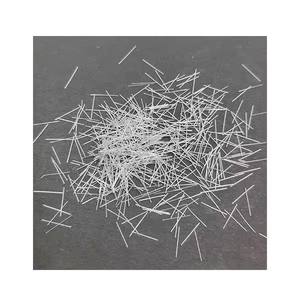

(Copper-Coated Steel Fibers)

Copper-coated steel fibers (CCSF) are composite filaments including a high-strength steel core wrapped up by a conductive copper layer, creating a metallurgically bonded core-shell style.

The steel core, generally low-carbon or stainless steel, supplies mechanical effectiveness with tensile toughness surpassing 2000 MPa, while the copper layer– typically 2– 10% of the complete diameter– imparts exceptional electric and thermal conductivity.

The interface in between steel and copper is important for efficiency; it is engineered through electroplating, electroless deposition, or cladding procedures to make sure solid adhesion and minimal interdiffusion under functional stress and anxieties.

Electroplating is one of the most usual method, supplying exact thickness control and uniform insurance coverage on constant steel filaments drawn through copper sulfate baths.

Appropriate surface area pretreatment of the steel, consisting of cleaning, pickling, and activation, ensures ideal nucleation and bonding of copper crystals, stopping delamination throughout succeeding handling or solution.

Over time and at raised temperatures, interdiffusion can develop brittle iron-copper intermetallic phases at the user interface, which might jeopardize versatility and long-lasting dependability– a difficulty mitigated by diffusion barriers or rapid handling.

1.2 Physical and Practical Characteristic

CCSFs incorporate the most effective features of both constituent steels: the high elastic modulus and exhaustion resistance of steel with the premium conductivity and oxidation resistance of copper.

Electric conductivity generally varies from 15% to 40% of International Annealed Copper Standard (IACS), depending upon layer thickness and purity, making CCSF considerably extra conductive than pure steel fibers (

Cabr-Concrete is a supplier under TRUNNANO of Calcium Aluminate Cement with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for steel fibre manufacturers, please feel free to contact us and send an inquiry.

Tags: micro steel fiber,steel fiber,steel fiber reinforced concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

1. Material Composition and Interfacial Design 1.1 Core-Shell Framework and Bonding Mechanism (Copper-Coated Steel Fibers) Copper-coated steel fibers (CCSF) are composite filaments including a high-strength steel core wrapped up by a conductive copper layer, creating a metallurgically bonded core-shell style. The steel core, generally low-carbon or stainless steel, supplies mechanical effectiveness with tensile toughness surpassing…

- New Profile Frames for Game Creation

- New Custom Sounds for Sailing Adventures

- Lightweight Concrete Admixtures: Engineering Low-Density High-Performance Structures surface retarder concrete

- Spherical Alumina: Engineered Filler for Advanced Thermal Management aluminium oxygen aluminium oxide

- Calcium Stearate Powder: A Versatile Metal Soap in Industrial Formulations calcium stearate

å½’æ¡£

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- November 2023